Vibration Simulator for Customer orders

▶ We provides the system to simulate the abnormal condition of the equipment.

▶ Components is machined to high tolerances so it can be operated without conflicting vibration.

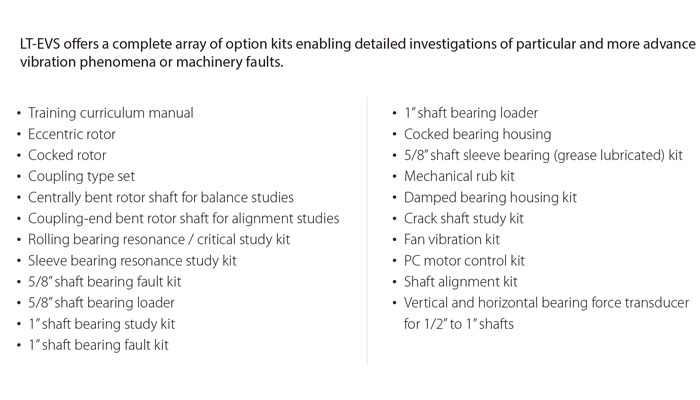

▶ Various faults can be introduced either individually or jointly in a totally controlled environment, making the LT-EVS the best tool available for learning machinery diagnosis.

▶ Gain an in-depth understanding of different vibration signatures, controlled experiments on a device that emulates real world machinery are needed.