The Benefits of Machine Analysis

The Success of a company often depends on the continued, safe and productive operation of rotating

machinery. An effective maintenance is vital to this kind of success. The quality of maintenance

determines how long the machines will run, how safe they are for the people working around them,

and how productive the machine will be. According to this, we are going to introduce the benefits of

our system , “MMDS”.

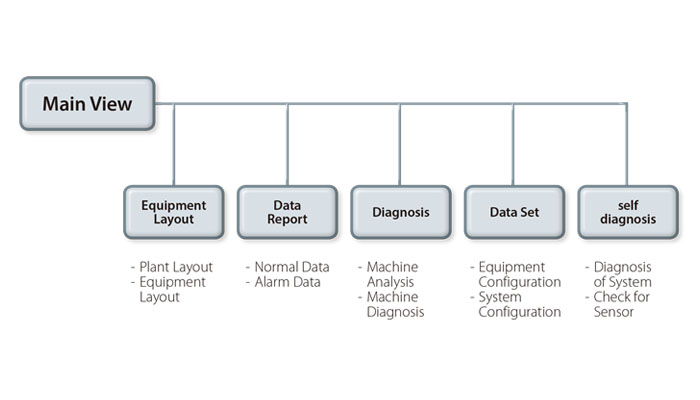

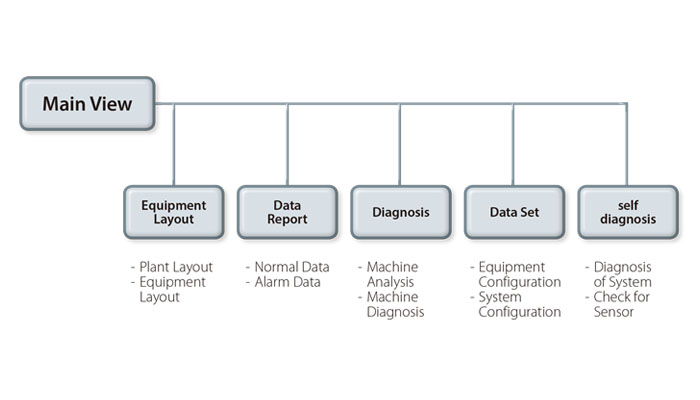

Measuring & Trend

[Measuring]

▶ Plant Layout : Display the condition about all equipments in the plant.

▶ Equipment Layout : Display the condition about selected equipment in the plant

( run or not, loaded or not, normal ,caution, damage etc)

[Trend]

▶ Trend graph : Display the trends of vibration or temperature about the selected equipment (hourly, daily, weekly, monthly)

▶ Trend Prediction : predict the trend of vibration based on the past data.

Measuring

Quantify the signal transformed from the vibration gathered during rotation. those are acceleration, velocity and displacement.

▶ Mode : Acc’ O/A RMS, Acc’ PEAK, Acc’ RMS. Velocity RMS. Displacement RMS, PEAK.

▶ Sensor : Acceleration, Velocity, Displacement, Temperature, Pressure, Rotation, etc.

▶ Equipment : Motor, Fan, Compressor, Pump, Gear Box, etc.

▶ Period : All the time, Random Measuring.

Vibration data Analysis

▶ Waveform Analysis - Visual identification of periodic and transient events in the sensor input signal

▶ Spectrum Analysis (FFT). Data in frequency domain helps to identify fault frequencies and relate them to the corresponding machine component conditions

▶ Analysis in acceleration, velocity, or displacement units. Multiple graphs can be compared for analysis. Interactive cursors and scaling, zoom, and other features

▶ Bearing Signal Enveloping helps in early identification of developing bearing faults